Engine Repair Tools

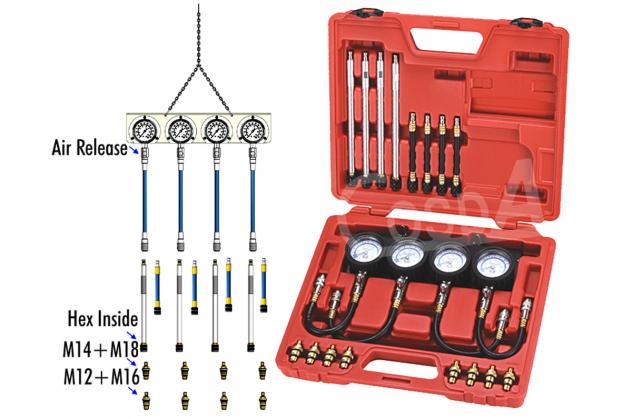

914-5728

•Main test for cylinder compression for nearly all gasoline vehicles.

•Quality of piston ring.

•Cylinder compression balance.

•Carbon deposit in combustion chamber.

•Test 4 cylinders at the same time provides more efficient test and could see balance quickly.

•High quality gauges provides accurate test analysis.

•Suitable for most 4, 6, 8 straight cylinder and V-shape engines.

•Available to compare 4 cylinders easily.

•Unique lock design on test adaptors can help to avoid adaptors stay in cylinder chamber after finish test

•Instruction:---

•1) Stop engine, raise vehicle bonnect and hook the test body on car.

•2) Disconnect the spark plug and wires. (fig.1)

•3) Choose suitable connection hose (steel / flexible) and suitable test adaptor.

•4) First cnnect test adaptor with connection hose tightly. Pull back the knurled hex-inside adaptor, thread test adaptor until the hex test adaptor fixes with connection hose. (fig.2) Install connect hose and test adaptor into spark plug holes. (fig.3) (can use hand or wrench to tighten the steel hose).

•5) Connect main body with connection hoses on after one. (fig.4)

•6) Start engine to run at least 4 compression strokes or until the pressure of gauge reading remains a fix level. (fig.5)

•7) Please refer to the manufacturer's maintenance manual about the cylinder standard compression.

Note: Could exchange the hose onto different cylinder for double check the test analysis. (fig.6)

•8) When finish the test, press release button under the gauge and disconnect test tool.

•Specification:---

•1) Main test device with 4 gauges:---

1-1) Gauge reading ( 0 - 300 psi)

1-2) 245mm length flexible hose with female coupling.

•2) Connection hose (hex inside thread):---

2-1) 260mm length steel hose.

2-2) 150mm length flexible hose. (for V-shape engines).

•3) Step test adaptor:---

3-1) M14x1.25P+M18x1.5P adaptor

3-1) M12x1.25P +M16x1.5P adaptor.

•Main test for cylinder compression for nearly all gasoline vehicles.

•Quality of piston ring.

•Cylinder compression balance.

•Carbon deposit in combustion chamber.

•Test 4 cylinders at the same time provides more efficient test and could see balance quickly.

•High quality gauges provides accurate test analysis.

•Suitable for most 4, 6, 8 straight cylinder and V-shape engines.

•Available to compare 4 cylinders easily.

•Unique lock design on test adaptors can help to avoid adaptors stay in cylinder chamber after finish test

•Instruction:---

•1) Stop engine, raise vehicle bonnect and hook the test body on car.

•2) Disconnect the spark plug and wires. (fig.1)

•3) Choose suitable connection hose (steel / flexible) and suitable test adaptor.

•4) First cnnect test adaptor with connection hose tightly. Pull back the knurled hex-inside adaptor, thread test adaptor until the hex test adaptor fixes with connection hose. (fig.2) Install connect hose and test adaptor into spark plug holes. (fig.3) (can use hand or wrench to tighten the steel hose).

•5) Connect main body with connection hoses on after one. (fig.4)

•6) Start engine to run at least 4 compression strokes or until the pressure of gauge reading remains a fix level. (fig.5)

•7) Please refer to the manufacturer's maintenance manual about the cylinder standard compression.

Note: Could exchange the hose onto different cylinder for double check the test analysis. (fig.6)

•8) When finish the test, press release button under the gauge and disconnect test tool.

•Specification:---

•1) Main test device with 4 gauges:---

1-1) Gauge reading ( 0 - 300 psi)

1-2) 245mm length flexible hose with female coupling.

•2) Connection hose (hex inside thread):---

2-1) 260mm length steel hose.

2-2) 150mm length flexible hose. (for V-shape engines).

•3) Step test adaptor:---

3-1) M14x1.25P+M18x1.5P adaptor

3-1) M12x1.25P +M16x1.5P adaptor.